Building Information 1

General Building Data

Building name – Calvin and Janet High Center for Worship and Performing Arts

Location - Grantham, Pennsylvania

Site – 600 College Avenue

Building Occupant Name – Messiah College

Occupancy or function types (type of building) – Places of religious worship and theater

Size (total square feet) – 94118 SF

Number of levels – 2 above grade, 1 below

Project Team

Owner’s Representative: Kathie Shafer

Architect: Greenfield Architects, LTD

CM: High Construction Com

Civil Engineer: Benatec Associates Inc

Structural Engineer: Providence Engineering

MEP Engineer: Barton Associates, Inc

Acoustical Consultant: Acoustic Dimensions

Audio/Visual Consultant: Acoustic Dimensions

Theater Consultant: Robert Davis, Inc

Dates of construction (start – finish): October 2009-September 2013

Actual cost information: $24 million

Project delivery method: CM at Risk

Architecture

High Center at Messiah College has become one of the finest facilities of campus due to acoustical and aesthetic qualities. Feasibility study for renovation and additions was conducted by Greenfield Architects design team on an existing Worship and Performing Arts Center at Messiah College. Existing building was 46,000 SF facility. The renovation and addition included a new 900-seat worship/performance hall, rehearsal rooms, graphic and sculpture studios/classrooms and other offices. Recital hall was converted into a black box theater with a new gallery level. Iconic, all-glass stair case connects three floors and can be entered from West façade. The main entrance is located on the North side. The building design compliments surrounding campus facilities and surrounding natural environment. High windows and big lobby spaces let it a lot of daylight and opens up a view to outside.

Major national model code/s:

2009 International Building Code (IBC)

2009 International Plumbing Code (IPC)

2009 National Electric Code (NEC)

2009 International Mechanical Code

2009 International Fire Code

2009 International Energy Conservation Code (IECC)

2009 International Fuel Gas Code (IFGC)

Americans with Disabilities Act (ADAAG)

2003 ANSI A117.1

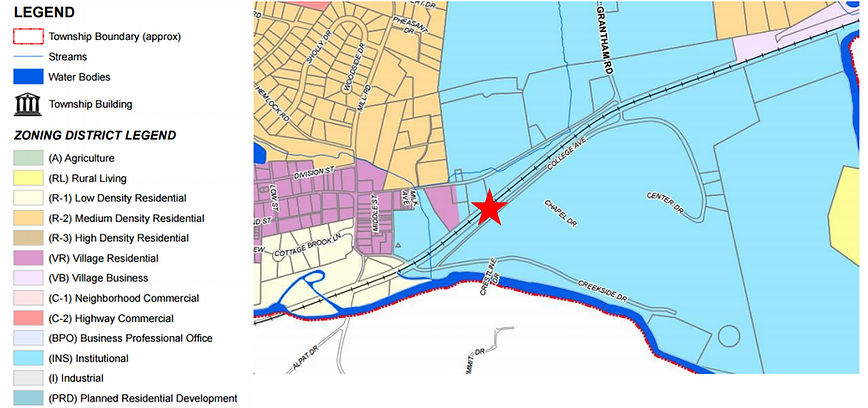

Zoning

The project is located in the zoning map planned under Zoning Ordinance #588 for the Township of Upper Allen, Cumberland County, Pennsylvania. According to para. 245- 157 Height Adjustments B (3), INS shall not exceed 55 feet. District is permitted to have a maximum height of 85 feet, provided that for each additional one foot above 55 feet the width of the each side yard is further increased by two feet. Further information can be found in: http://ecode360.com/8578219

Historical requirements of building or historical district where built: N/A

Building Enclosure

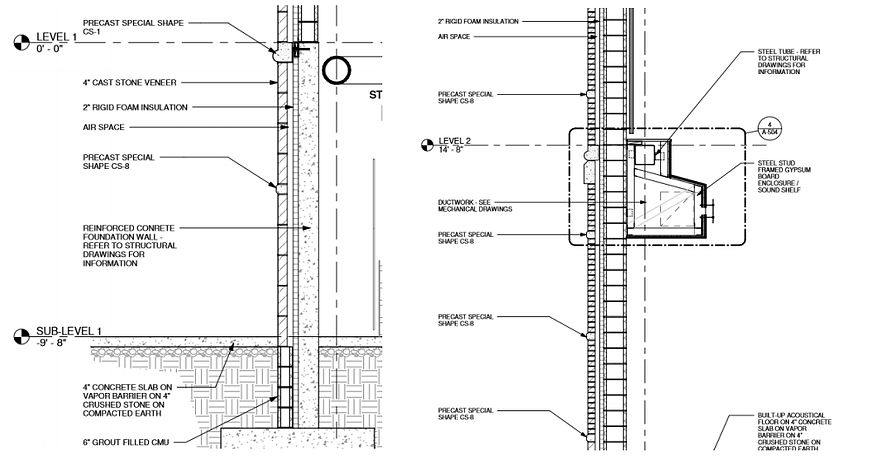

Building façades An insulated aluminum curtain wall system with IGL glazing was used on the corner stairs on the West façade and North Lobby. The most common exterior wall consists of cast stone veneer/masonry veneer with 2” rigid insulation, air space and CMU wall. Detailed section views are shown below. Since acoustics was one of the main design concerns, steel stud framed gypsum board enclosure/sound shelves and built-up acoustical floor on concrete slab were utilized to improve acoustics in spaces. Typical curtain walls are constructed with an insulated aluminum curtain wall with IGL glazing. Also prefinished aluminum composite panel cladding is shown, which provides shading for the space.All images are courtesy of Barton Associates, Inc.

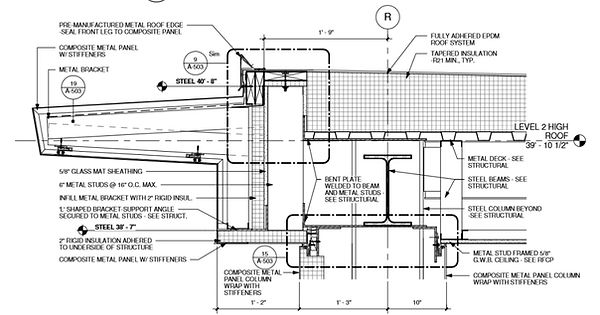

Roofing

Fully adhered EPDM roof system was used for roofing. One of the most typical roof sections for the building is shown below. Image shows detailed parts of cornice and roofing.

Typical parapet and roof section view of the building is shown below.

Sustainability Features

The idea of designing and building Calvin and Janet High Worship center was thought through and planned out through 8 years of design and construction. Top priority for of the building was acoustics. So acoustics could not be jeopardized and required a lot of funding. Due to cost, the third floor was eliminated and floor plans reorganized to meet the program. However, regardless of the all the difficulties, design team did their best to incorporate sustainable systems. The envelope of the building includes tall windows to harvest natural sunlight. Mechanical system of the building uses high-efficiency boilers to cut down on energy use. Building Automation System was programmed to save on energy spending by incorporating set-point schedule and occupancy schedules.

Construction:

The project delivery method for Calvin and Janet High Center was Construction Manager at Risk. Construction services were provided by High Construction Company. MEP services summed up to be $24 million. Total cost of construction is not available.

Budget was fixed and strict, thus it could not be compromised. Acoustics was utmost important part of construction. 50 yards away from High Center, there is a busy train station. Main goal was to isolate sound both from outside and escaping from sound sensitive spaces. Throughout the construction, third floor was eliminated and program was fit into smaller square footage due to budget constraints. As a result, project was completed successfully and met all the set goals and building standards.

Electrical:

Calvin and Janet High Center for Worship and Performing Arts utility feed supplies power to an existing PP&L main switchgear and an existing PP&L 750 kVA transformer. PP&L main switchgear encompasses majority of first and second floor, while HSB secondary switchboard encompasses mainly theatrical lighting. There are 41 panels in total. 19 panels has a rating of 277/480V, and 22 panels have rating of 120/208V. Based on Power System Engineering done by Schneider Electric, maximum available three-phase short-circuit current is 3327A at 12470V.. The emergency system consists of two 150 kW generators running in parallel through the panel EDP to four downstream circuits.

Lighting:

Calvin and Janet High Center is classified as a performing arts theater with a maximum allowed lighting power density (LPD) of 1.6 W/SF as dictated by ASHRAE 90.1. The building complies with ASHRAE, since internal lighting power density is 1.1 W/SF. There are photocell/astronomical time switch imbedded on exterior lights. Automatic lighting shutoff controls are installed for energy saving. Each space has a manual control that allows reducing the connected load by 50 percent by switching some lamps independently of other lamps. Compact Fluorescent, Linear Fluorescent, Halogen and LED fixtures are installed throughout the building. Incandescent lamps were installed for theatrical/photographic lighting in Black Box Theatre room. Sculpture spotlights, symphony hall entrance, and sign lighting use LED lamps to cut on energy usage. Downlights, cylinders, pendants, and wall washes utilize compact fluorescent lamps. Bollards, general wall sconces and wall sconces at exits have fluorescent lamps. Halogen lamps were installed for accent lighting and rooftop spotlights.

Structural:

Foundation walls at Calvin and Janet High Center are supported by step footings. Steel and concrete composite beam floor system with W12 wide flange columns are used throughout the project. New footings were attached into existing footings with #5 dowel bars 18’ long at 12” O.C. drill and epoxy grout. Floor slab is made of 4” or 6” thick concrete slab reinforced with 6x6-W1.4xW1.4 WWF on 10 mil vapor retarder on 4” compacted stone. Structure is cross-braced and diagonally braced to meet wind and seismic loads. Shear walls are used around elevator shafts and stairs to meet lateral forces. Structural slab is 3 ½” normal weight concrete over 2” deep x 20 gage galvanized composite metal deck. Additional concrete is on it due to adjoining depressed slab or sloped floor.

Mechanical:

The primary air-side components of the mechanical system are located in the mechanical room on the first floor and on the rooftop. Air distribution system is a 4-pipe VAV Air handler with supply and return fan. Calvin and Janet High Center for Worship and Performing Arts utilizes two chillers coupled with 14 air handling units (with varying capacities) and ductless split system to provide cooling for the building. Two high-efficiency boilers, unit heaters, baseboard radiation units and control reheat units provide heating to the building. Building Automation System operates reading the information from temperature/humidity and CO2 sensors located in the zones to meet Indoor Air Quality standards. Sequence of Operation of controls for mechanical systems are provided by ARCNET Router. Extremely powerful and high-speed router connects hundreds of controls and executes complex control strategies. WebCTRL is a building automation offers local monitoring and distant access. Building management functions are setting and changing schedules, adjusting set points, viewing alarms, and access to energy usage.

Fire Protection:

Entire building is fully sprinkled. Fire protection system consists of a combined wet pipe sprinkler and standpipe system. Sprinkler system is zoned floor by floor. The wet pipe sprinkler system is hydraulically designed and based upon a minimum of 0.10 GPM per SF over the most remote 1500 SF area with sprinkler heads spaced at a maximum of 225 SF per head. The wet standpipe system is hydraulically designed and based upon a total flow rate of 1000 GPM. Fire pump is capable of flowing 1000 GPM at 90 PSI boost. Water and fire service room is located on the first floor.

Transportation:

There are seven stairs in the perimeter of building and two passenger elevators in the building.

Telecommunications:

Distributed antenna system (cell boost) at Calvin and Janet High Center contain three expansion hubs. 8 Remote access units on each 1st and 2nd levels, as well as 2 on the Mezzanine/Blackbox level are connected to expansion hubs. Each level has a telecommunication room, and service all the rooms on the respective level. Telecommunication outlets are installed in all offices and practice rooms.